All Of It Made Possible With The Hydraulic Press

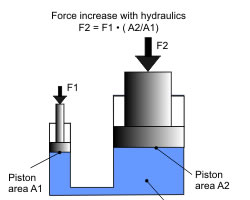

The concept of the hydraulic press is based on Pascal's theory, which states that when pressure is applied on fluids in an enclosed system, the pressure throughout the system always remains constant. In simple words, a hydraulic press is a machine that makes use of the pressure exerted on the fluids to crush something.

Joseph Bramah invented the hydraulic press, hence it is also known as the Bramah Press.

How the Hydraulic Press works

Since the hydraulic press works on the basis of Pascal's Law, its working is similar to the one of the hydraulic system. A hydraulic press consists of basic components used in a hydraulic system that includes the cylinder, pistons, the hydraulic pipes, etc.The working of this press is very simple. The system comprises of two cylinders, the fluid (usually oil) is poured in the cylinder having a small diameter. This cylinder is known as the slave cylinder.

The piston in this cylinder is pushed so that it compresses the fluid in it that flows through a pipe into the larger cylinder. The larger cylinder is known as the master cylinder. The pressure is exerted on the larger cylinder and the piston in the master cylinder pushes the fluid back to the original cylinder.

The force applied on the fluids by the smaller cylinder results in a larger force when pushed in the master cylinder. The hydraulic press is mostly used for industrial purposes where a large pressure is required for compressing metals into thin sheets. An industrial hydraulic press uses the material to be worked upon along with the help of the press plates to crush or punch the material into a thin sheet.

Uses Of A Hydraulic Press

A hydraulic press is used for almost all industrial purposes. But basically it is used for transforming metallic objects into sheets of metal. In other industries, it is used for the thinning of glass, making powders in case of the cosmetic industry and for forming the tablets for medical use. The other common uses of the hydraulic presses are as follows:

- For crushing cars. A hydraulic press is the heart of any car crushing system. In this process, a hydraulic motor applies a large pressure on the fluids into the cylinders. The fluid pressure makes the plates rise and with a large force, the plate is driven on the car thereby crushing it.

- Fat-free cocoa powder. While processing the cocoa beans, a liquid known as chocolate liquor is derived. For making fat-free cocoa powder, this liquid is squeezed out in a hydraulic press. After this stage, this liquid is processed further to make a powder. The powder thus derived is cocoa powder, which is fat-free.

- For sword making. In the process of making swords, a hydraulic press is used to give a flat shape to the raw steel.

Types Of Hydraulic Press

There are many different types of hydraulic presses catering to the various requirements of industries. Some of them are as follows:

• Arbor presses: These presses are usually used when the work involved is not of a heavy- duty nature. These presses come in a variety of sizes and specifications. But compared to other hydraulic presses, they do not compress large amounts of pressure required to generate more output. Arbor presses are used in processes like piercing holes into metals, stamping, to flatten metals, tearing, marking inscriptions, etc.

• Laminating presses: Unlike other hydraulic presses that are operated automatically, these presses make use of manual labor. Laminating presses have two openings that are known as plates. One is used for heating whereas the other is used for cooling. This makes the lamination process comparatively faster. Through these presses, materials like polymer can be laminated onto paper and metal. In case of laminating presses, the plates are usually heated with oil or through electricity. A laminating press is also used for common uses such as laminating the identity cards, certificates and even book covers. In this way, laminating presses facilitates fast and easy lamination for industrial and domestic needs.

• C- frame presses: These presses have a 'C' like shape, which is specifically designed to maximize the floor space for the workers in order to move around easily at the workplace. Unlike other presses that have multi-processes, the C- frame presses only include a single press application. Its application includes straightening, drawing and mostly includes assembling work. C- frame presses come in a variety of weights. The C- frame presses are also available with extra features such as wheel stands and pressure gauges.

• Pneumatic presses: These presses are the most basic hydraulic presses used in industries because they compress the air to create a pressure in order to gain movement. The advantage of pneumatic presses is that the operations are performed fast whereas the disadvantage of this press is that it cannot create extremely high pressures, as other hydraulic presses are able to create. The pneumatic presses are often used in car and aircraft brakes system. The industrial uses of pneumatic presses would include assembling, drawing, punching, etc. A pneumatic press usually requires a full time operator and for the sake of his safety, additional safety accessories such as electrical safety devices are also included.

• Power presses: These presses are used in large industries that demand the use of heavy machinery and equipments. There are 2 kinds of power presses on the basis of the type of clutch used. They are full revolution and part revolution clutch. In case of a full revolution clutch, the clutch cannot be disrupted until and unless the crankshaft makes a full revolution. In case of part revolution, the clutch can be disrupted at any time, before or after the full revolution. Power presses involve a lot of danger because of the heavy operations associated with it. A lot of safety measures are taken while using power presses.

• Assembly presses: These presses use the extreme pressure generated by the pistons and the hydraulic fluids to assemble and maintain the parts.

• H- frame presses: These presses have a peculiar 'H' shape and are capable of handling more that one press application.

Safety Measures

As of today, hydraulic presses are available in both the categories, i.e., automatic and manually operated. In case of manually operated hydraulic presses, many safety measures have to be taken such as using interlocking and barrier guards.

Benefits Of the Hydraulic Press

Unlike their mechanical counterparts, hydraulic presses can compress any material to a full extent. Also, hydraulic presses take only half of the space that the mechanical ones take because they have the ability to compress a large pressure in a cylinder having a less diameter.

|